The Differences of Stainless Steel Vs. Brass Hardware

There are always ongoing debates on which materials are ideal whether that is stainless steel, chrome, brass, or any other alloy material. Do you choose stainless steel hardware or brass hardware? It is important to understand the differences between stainless steel and brass. First we have to define and understand the key differences.

Stainless Steel – is a corrosion-resistant alloy of iron, chromium, and in some cases, nickel, and other metals.

Brass – a yellow alloy of copper and zinc.

Understanding Stainless Steel

Stainless steel has many unique values that make it a powerful candidate in materials selection. Engineers, specifiers, and designers often underestimate or overlook these values because of what is viewed as the higher initial cost of stainless steel. However, over the total life of a project, stainless steel is often the best value option. Corrosion resistance is a huge factor in stainless steel versus other materials. Lower alloyed grades resist corrosion in atmospheric and pure water environments, while high-alloyed grades can resist corrosion in most acids, alkaline solutions, and chlorine-bearing environments. You can find stainless steel material used in food processing, hospitality industries, and wastewater management due to its incredible resistance to corrosion.

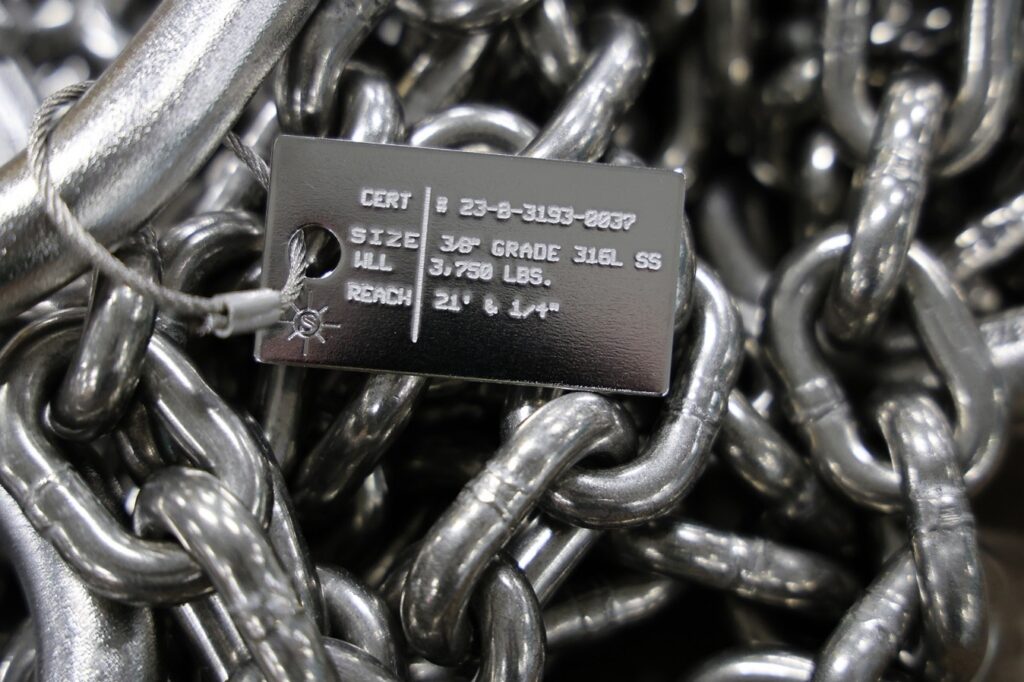

Strength is also an important factor to consider especially when it comes to industries such as lifting and rigging. Most common types of stainless steel tend to be stronger than the most common types of brass. Stainless steel also has substantial fire, heat, and impact resistance. Special high Chromium and Nickel-alloyed grades can resist scaling and retain strength at high temperatures. Stainless steel is also considered a “Green” material. Stainless steel products complete their service life. There is less concern about disposal since this material is 100% recyclable. In fact, over 50% of new stainless steel comes from old melted stainless steel scrap, thereby completing the full life cycle.

Understanding Brass

Brass is made from copper and zinc, typically in a 2:1 ratio. When it comes to thermal and electrical conductivity, brass is among the most conductive metals in the world, while stainless steel is significantly less so. Brass may be as much as 15 times more conductive than stainless steel depending on the specific composition. A distinct and clear feature of brass versus other materials is their aesthetic properties. Brass, as an alloy of copper, falls under the category of “red metals”. Traditional brass is yellowish-gold in color, while some alloys may be darker and closer to bronze. When you have a project where aesthetics matter most, this would be an important decision when deciding on materials.

Brass has a long history dating back to the Victorian era. It has experienced a resurgence in design circles over the years, with Unlacquered Brass providing warm, inviting tones in modern and traditional settings. This material is used in a lot of bathroom and kitchen fixtures.

Do I Choose Stainless Steel or Brass Hardware?

It is important to understand what factors are most important for your specific project when choosing Brass or Stainless Steel. When it comes to polished metal alloys, two of the most commonly used throughout the world are brass and stainless steel. Both of these alloys have played an integral role in the history of architecture, manufacturing, and more. They have also helped expand our capacity for construction and served as the building block of innovation. Brass and stainless steel are known as two of the greatest creations of our time.

When evaluating brass vs. stainless steel, you can read the benefits we mentioned above and evaluate their properties and characteristics. Depending on what project or application you have, it is important to understand factors such as strength, corrosion resistance, long-term value, conductivity, appearance, and more. Ultimately, the right choice depends on the specifics of your project. There are cases where the right metal may be more clear-cut.

Stainless steel generally makes more sense in instances where structural strength is paramount. This can apply to construction projects, rigging and lifting, architectural applications, etc. Brass, on the other hand, is favored more in electrical, heating, and plumbing applications. When it comes to design and aesthetics, the right choice depends entirely on the creative vision for the project. If you have any questions on the benefits of stainless steel, you can always contact the Suncor Stainless Team and we would be more than happy to help!

SUNCOR STAINLESS: THE LEADING MANUFACTURER OF STAINLESS STEEL HARDWARE AND COMPONENTS.

To learn more about the world’s most complete and highest quality sources for stainless steel hardware and custom parts – visit our Suncor Stainless website. This Plymouth, MA-based company offers a variety of the highest quality stainless steel hardware for industrial, marine, architectural, commercial, government, and OEM markets.

For more information on our stainless steel hardware and custom parts, you may contact Suncor Stainless at 1-800-394-2222 or by completing the Contact Us Form.

Sources:

https://polishedmetals.com/brass-vs-stainless-steel/

https://rotaxmetals.net/brass-vs-stainless-steel-which-one-should-you-use-for-your-project

Recent Comments