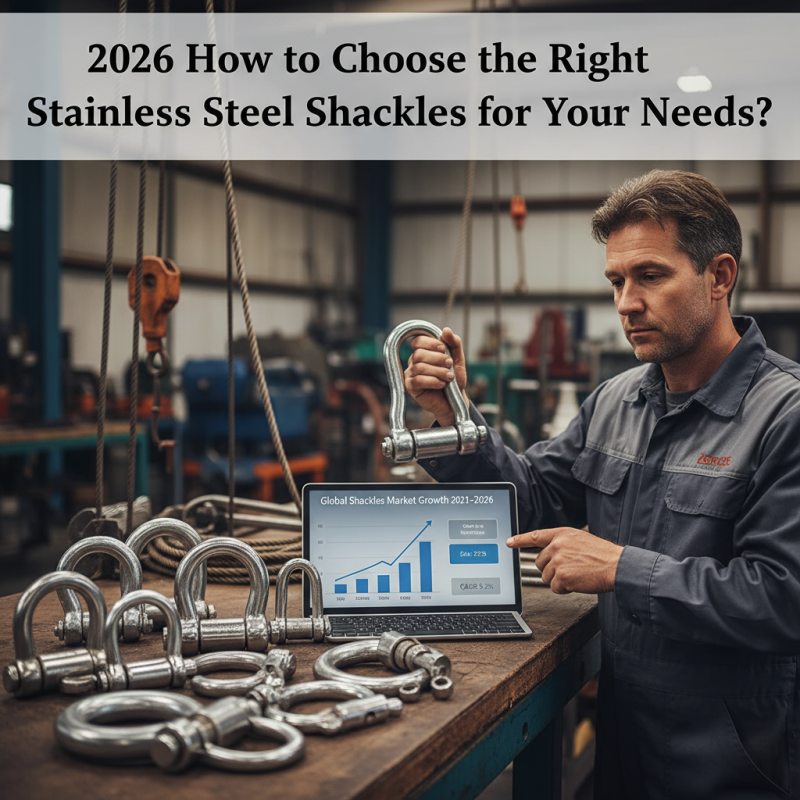

When selecting stainless steel shackles, understanding your specific requirements is crucial. The global market for shackles is projected to grow significantly, driven by rising demand in various industries, including marine and construction. According to a report by Market Research Future, the stainless steel shackles segment is expected to witness a compound annual growth rate of 5.2% from 2021 to 2026.

Expert James Carter, a leading figure in rigging technologies, emphasizes, “Choosing the right stainless steel shackles is critical for safety and reliability.” His insight highlights the importance of material quality, load capacity, and design features. Each application may require different specifications. For instance, some environments may demand higher corrosion resistance. This nuanced selection process can be overwhelming, often leading to mistakes.

It is essential to consider factors such as size, type, and usage context when choosing stainless steel shackles. Rushing this decision can have serious implications. Ensuring you ask the right questions helps prevent common pitfalls. Features like pin style and working load limits must be matched to your specific applications. There’s a lot at stake, and clarity in your selection process can save time and resources in the long term.

When choosing stainless steel shackles, understanding the types is vital. Shackles come in various designs, including bow and D types. Bow shackles offer a larger opening, suitable for multiple connections. This can be important for heavy-duty tasks. The D shackle, while compact, can handle significant loads.

A report from the International Marine Organization states that corrosion resistance is key for shackles, especially in marine environments. Stainless steel types 304 and 316 are common. Type 316 has molybdenum, making it more resistant to pitting. This can be crucial for longevity in saltwater conditions.

Tips: Always consider the working load limit (WLL). Failing to select appropriately can lead to failures. Regular inspections help identify corrosion. Note that some users overlook the importance of periodic checks, which can be a costly mistake. Remember, the right choice can enhance safety and performance.

| Type of Shackle | Material Grade | Working Load Limit (WLL) | Typical Use Cases | Advantages |

|---|---|---|---|---|

| Bolt Type Shackle | AISI 304 | 3,000 lbs | Marine applications, lifting | Secure fastening, easy removal |

| Anchor Type Shackle | AISI 316 | 4,500 lbs | Docking, mooring lines | Corrosion resistance in saltwater |

| D-Shackle | AISI 304 | 2,000 lbs | Rigging, general purpose | Versatile design, strong load capacity |

| Round Pin Shackle | AISI 316 | 6,000 lbs | Heavy lifting, construction | Resistant to bending and fatigue |

When choosing stainless steel shackles, several key factors come into play. First, consider the type of stainless steel. AISI 316 offers excellent corrosion resistance, making it suitable for marine environments. In contrast, AISI 304 is often cheaper but may not last as long in harsh conditions. Be mindful of the environment where you’ll use the shackles; longevity can vary based on exposure to saltwater or chemicals.

The size and load capacity are also crucial. Shackles come in many sizes, so knowing your application helps. A shackle too small may break under stress, while an oversized one can be cumbersome. It’s important to ensure that the working load limit meets your needs. Often, people overlook this detail, which can lead to dangerous situations.

Additionally, the design of the shackle matters. Bow shackles offer a wider handle, while D shackles are more compact. Each style serves different purposes. However, many users struggle to understand which fits their needs best. Reflecting on personal experiences can guide future decisions. Ensuring that the chosen shackle aligns with both safety and functionality is essential for effective use.

When choosing stainless steel shackles, load capacity and safety ratings are crucial. Shackles are commonly rated based on their working load limit (WLL). Typically, a shackle's WLL ranges from 1000 kg to over 100 tons. It is essential to select a shackle that can handle the weight you intend to lift. A mismatch can lead to failure or accidents.

Safety ratings are another vital aspect. Look for shackles that meet international standards, such as those established by the American Society for Testing and Materials (ASTM). A report by the Lifting Equipment Engineers Association (LEEA) indicates that using shackles with proper certification significantly reduces risks. Shackles with a safety factor of at least 5:1 are often recommended. This means that the breaking strength should be at least five times the WLL.

Consider the application as well. Some shackles are designed for marine or industrial use. Environment and exposure to elements can affect their performance. Regular inspection is necessary. Sometimes, shackles may appear fine but can have hidden damage. This is a reminder that visual checks alone don't guarantee safety. Always keep a close eye on the shackles you use, as their reliability can be impacted over time.

When selecting stainless steel shackles, corrosion resistance is a crucial factor. Stainless steel grades vary significantly in their resistance to corrosion. For marine environments, grade 316 is often recommended due to its exceptional resistance to chloride-induced pitting. According to industry reports, components made of 316 stainless steel can last up to ten times longer than those made from inferior materials in harsh environments.

It’s important to understand that not all stainless steels are created equal. For less demanding applications, grade 304 may suffice. However, it is 25% less resistant to corrosion compared to grade 316. This comparison highlights the necessity of knowing the specific requirements of each application. For instance, using 304 in coastal areas might lead to premature failures. Real-world data indicates that 40% of stainless steel failures are attributed to improper material selection.

When evaluating your options, consider the specific conditions your shackles will face. You might question the cost-benefit ratio of investing in higher-grade materials. Yet, the longevity and performance of thicker, more resilient stainless steel can outweigh the initial expense. Investing in quality can prevent costly repairs and replacements down the line.

Maintaining and inspecting your stainless steel shackles is crucial for safety and performance. Regular checks can prevent accidents and ensure reliability. Look for signs of wear, such as rust or deformation. These indicators are red flags. Taking action early can save time and money later.

Tip: Clean your shackles after each use. Use a soft brush to remove dirt and grime. This simple step helps prevent corrosion. Inspect for cracks and ensure the pins function smoothly. Pay attention to any unusual noises during use. These could signify that a shackle is compromised.

In time, shackles can become worn or damaged. Replace them when you notice significant wear. Don't overlook the importance of proper storage. Store shackles in a dry place to minimize moisture exposure. Remember, even the best shackles need care. Regular maintenance extends their lifespan, ensuring they perform optimally when you need them most.